MM TIMBER LOG: Der Zweite Wald

Fakt ist: Jeder Kubikmeter Holz, der CO₂-intensive Materialien ersetzt, spart im Schnitt 1,1 Tonnen CO₂ und speichert Kohlenstoff über Jahrzehnte. Damit wird der Holzbau zum entscheidenden Hebel für klimafreundliches Bauen. CEO Richard Stralz zum Zweiten Wald und dem Zukunftsbaustoff Brettsperrholz, der unbedingt strategisch in die urbane Stadtentwicklung integriert werden muss.

Welche Bedeutung hat der „zweite Wald“ im Kontext moderner Stadtentwicklung?

Der ‚zweite Wald‘ bezieht sich auf den Holzbau, denn Holzhäuser binden CO2 wie unsere Bäume in den Wäldern. Je mehr Holz wir verbauen, desto mehr Kohlenstoff wird also gespeichert. Viele Holzhäuser machen dann sozusagen den ‚zweiten Wald‘ aus. Der Wohnungsbedarf vor allem in den Städten ruft förmlich nach der Holzbauweise, eine gezielte Planung von Nachverdichtung, Neubau und Sanierung mit Holz ist ein wertvoller Beitrag zur Erreichung der Klimaziele.

Wie kann Holz als Zukunftsbaustoff die Stadtentwicklung nachhaltig beeinflussen?

Holz vereint wesentliche Vorteile: Es bindet CO2 langfristig, ermöglicht durch Vorfertigung hochpräzise und schnelle Bauprozesse, hat weniger Gewicht als traditionelle Baumaterialien bei gleicher Festigkeit und ist daher prädestiniert für Aufstockung und Nachverdichtung und eröffnet durch die einfache Bearbeitungsmöglichkeit architektonische Freiheiten. Zudem ist Holz durch und durch ein regionaler Rohstoff. In hybriden Systemen – etwa in Kombination mit Beton für große Spannweiten und höhere Schallschutzanforderungen – wird Holz auch im urbanen Hochbau uneingeschränkt einsetzbar.

Welche Rahmenbedingungen braucht es, um den Holzbau im Kampf gegen den Klimawandel zu stärken?

Um den Holzbau zu fördern, sind politische Rahmenbedingungen erforderlich, die die gesamte Holzwertschöpfungskette – vom Forst bis zum Holzbau – unterstützen

und ihre Rolle im Kampf gegen den Klimawandel anerkennen. Dazu gehören Anreize für den Holzbau generell und die Förderung von Bildungsinitiativen, die das Wissen über Holz als Baustoff verbreiten.

Welche Bedeutung haben Fachleute wie Zimmerer für die Zukunft des Holzbaus?

Zimmerer sind das operative Rückgrat des Holzbaus. Sie übersetzen die industrielle Präzision vorgefertigter Elemente in bauliche Realität. Holz ist leicht, zugleich leistungsstark und lässt sich schnell montieren – doch all diese Vorteile entfalten sich nur durch qualifizierte Fachkräfte. Zudem treiben moderne Zimmerer die Digitalisierung der Baustelle voran und sichern so die Innovationskraft der gesamten Branche.

Stichwort Feuchteschutz und Standardisierung: Welche Herausforderungen und Lösungen gibt es im Holzbau?

Feuchtigkeit ist der größte Feind des Holzes, da sie zu Schäden und einer verkürzten Lebensdauer führen kann. Um dies zu vermeiden, ist es entscheidend, dass Handwerker Holz so verbauen, dass es vor Wasser geschützt ist. Dies erfordert eine sorgfältige Planung und den Einsatz von Sensorik, um Feuchtigkeit frühzeitig zu erkennen und zu kontrollieren.

Durch Standardisierung wird Wohnraum leistbarer?

Richtig. Derzeit sind viele Holzbauprojekte noch stark individualisiert, was hohe Produktionskosten bedeutet. Durch die Einführung standardisierter Bauteile – also eines Baukastensystems – und wiederholbarer Prozesse können diese Kosten reduziert werden, ohne die Architektinnen und Architekten zu sehr in ihrer Kreativität zu

beschränken. So wird Holzbau nicht nur klimafreundlich, sondern auch ein zentraler Hebel für leistbaren Wohnraum.

Artikel erschienen in: https://www.businessmonat.at/jaenner-2026

Hope to give - Christmas donation handover

On behalf of all Mayr-Melnhof Holz employees, Stefan Hörnicke, Managing Director of MM Holz Wismar, and Julia Nietruk, Internal Sales Representative at MM Holz Wismar, presented our MM Holz Christmas donation for 2025 to the "Licht am Horizont" association.

Martina Krimmling, 1st Chairwoman, and Melanie Fischer accepted the donation cheque on behalf of the association and expressed their sincere thanks for the generous support on behalf of the entire association.

The joy is great: with our contribution, we are supporting children, young people and their families who are in material, financial or emotional distress and helping those who are dependent on solidarity and support.

We hope that our donation will bring a smile to the faces of one or two families and give them a ray of hope.

More about "Licht am Horizont": https://www.lichtamhorizont.de/

Photos: MM Holz Wismar

Klementifeier der Standorte Leoben und Gaishorn

Tradition trifft Spaß.

Mitarbeiterinnen und Mitarbeiter aus Leoben und Gaishorn kamen dieses Jahr wieder im Freizeitzentrum Zechner zur traditionellen Klementifeier zusammen.

Der Heilige Klemens, Schutzpatron der Holzarbeiterinnen, dessen Namenstag am 23. November gefeiert wird, hat in unserem Unternehmen seit Jahrzehnten einen festen Platz im Jahreskreis. Umso mehr freut es uns, dass auch heuer wieder unsere Klementifeier stattfand.

Richard Stralz, CEO Mayr-Melnhof Holz Holding AG, begrüßte die Mitarbeiter*innen und ließ das Jahr 2025 Revue passieren. In seinem Rückblick wurden Highlights und Erfolge des Jahres 2025 präsentiert. Eigentümer Franz Mayr-Melnhof-Saurau bedankte sich ausdrücklich bei allen Mitarbeiter*innen für ihren unermüdlichen Einsatz und die hervorragende Arbeit im vergangenen Jahr.

Ein ausgezeichnetes Buffet wurde mit Köstlichkeiten der Süßen Boutique getoppt. Beim Christbaumgewinnspiel wurden sieben Christbäume verlost – die Gewinnerinnen und Gewinner wurden von den beiden Glücksengerln, unserem Eigentümer Franz Mayr-Melnhof-Saurau und seiner Frau Patricia Mayr-Melnhof-Saurau, gezogen. Für Unterhaltung war bestens gesorgt: Nagelstöcke, eine Basketballwurfmaschine sowie eine Fotobox sorgten für Spaß und viele lustige Momente. Die ein oder andere Tanzeinlage durfte natürlich auch nicht fehlen, angeleitet von unseren Line-Dance Mädls. Musikalisch wurde der Abend von einem DJ begleitet.

Eine rundum gelungene Klementifeier, bei der Tradition auf Spaß traf und das Miteinander im Mittelpunkt stand.

Fotos: Hiebler-Liebminger, Leitner, Kramzer

NATURALLY WITH GREEN ENERGY FROM OUR OWN SOURCE: ELECTRIC TRUCK SAWN TIMBER SHUTTLE LEOBEN – GAISHORN

Sustainability has always been part of Mayr-Melnhof Holz's DNA, as demonstrated by a new project: two modern electric trucks will now be used to supply a large proportion of the sawn timber required at the Gaishorn site.

The sawn timber, produced at the traditional sawmill in Leoben, is delivered in 12 to 14 trips per day – currently accounting for up to 75% of the daily transport volume of sawn timber to the plant in Gaishorn – where it is processed into glued laminated timber and cross-laminated timber. Transportation takes place in two shifts from 6:00 a.m. to 10:00 p.m. Mayr-Melnhof Holz has signed a five-year contract with Herbert Temmel GmbH for this purpose.

The electric trucks are, of course, charged with green electricity! This is generated in the company's own biomass power plant with four boilers, where the bark of the round timber is converted into electricity and heat, in the new 3,800 kilowatt peak photovoltaic system, and in two hydroelectric power plants in the Göss-Graben.

To ensure that the trucks are ready for use, five loading bays have been set up in the sawn timber loading hall, which was built together with the new cross-laminated timber plant at the Leoben site and opened two years ago.

To ensure that the trucks are ready for use, five charging stations, each with a charging capacity of 350 kW, were installed in the sawn timber loading hall, which was built together with the new cross-laminated timber plant at the Leoben site and opened two years ago.

While the sawn timber is being loaded, the trucks simultaneously charge their batteries (the battery capacity is 500 kWh). This means that the time is used twice.

Some data:

• Distance between Leoben and Gaishorn: 106 km (round trip)

• Consumption on one route: 142 kWh

• Duration of a sawn timber loading: approx. 30 minutes

• Charging time: approx. 24 minutes at 350 kW – perfectly matched to the loading time

The advantages

• Significantly lower CO₂ emissions

• Use of green energy generated at the plant

• Another step toward sustainability

• A sign of the company's innovative strength

• Efficient use of loading and unloading times

Pictures: Hiebler-Liebminger, Kramzer

20 years of the Wood Festival in Ostrava

Anniversary edition. The Wood Festival in Ostrava, Czechia, took place for the 20th time this year. We are therefore all the more delighted that Mayr-Melnhof Holz Paskov has been a proud partner since the beginning.

The Wood Festival is an educational event for young and old alike. However, the focus is primarily on children, who can expand their knowledge of nature, forests and wood as a forward-looking raw material in a playful way.

The idea behind it is to make wood tangible and experiential in all its facets.

Our MM Holz stand was manned by our colleagues from the Paskov site, Lenka Gřes, Kateřina Martásková and Zbyněk Čech. They provided insights into sawn timber and pellet production. The children were able to get an idea of what wood chips, shavings, sawdust and pellets are and were allowed to try out a cutting plan for themselves. A traditional nail-hammering competition provided additional entertainment. Anyone who guessed the correct number of pellets in the jar was allowed to take a bag of pellets home with them. Another highlight for young and old alike was the MM Holz cube with a spruce seed.

We think it's great that even the youngest members of our generation are already being educated about ecology, nature and the conscious use of natural resources in everyday life.

Photos: Kocian, BUVi Promotion s.r.o

Former colleagues visit MM Holz – a day full of memories!

Reunions, valuable conversations, shared memories and nostalgic moments – that was the meeting of former colleagues who retired from MM Holz in Leoben before 2010.

After a welcome by Richard Stralz, CEO of Mayr-Melnhof Holz Holding, the focus was on sharing experiences, reminiscing and telling anecdotes. Everyone laughed and chatted over coffee and cake. The many old photos brought back touching memories and also provided many references to the present. Pictures of the installation and commissioning of plants many years ago, which are still in full operation today – well maintained. Or: in several photos, many active colleagues were identified as "apprentices of yesteryear" with one of their predecessors who acted as their trainer. Anecdotes naturally also revived the "feeling of that time".

The crowning highlight then awaited us afterwards: a factory tour in a nostalgic old-timer bus, across the round timber yard, along the sawmill hall to the new cross-laminated timber plant, which we also visited. At this point, we would like to express our sincere thanks to the Zottler company for this special trip and the charming journey through time!

The meeting came to a pleasant close with a joint lunch. There was still plenty of time to chat about "the good old days" and reminisce.

Photo: Leitner

Langer Tag der Energie - Mayr-Melnhof Holz Leoben opened its doors

Langer Tag der Energie, took place throughout Styria on 28 June 2025 and Mayr-Melnhof Holz once again invited visitors to take a look behind the scenes.

Interested visitors had the opportunity to tour the pelletising system and the biomass plant at the Leoben site. They were able to experience at first hand how energy is generated from wood.

We use 100 per cent of the valuable log, because sustainability is in our blood and that is exactly what we showed the guests on this day.

In the pelletising system, Gustav Lukanz gave the guests an insight into how the ecological heating material pellets are produced from sawdust and wood shavings. In the biomass plant, Andreas Spanblöchl showed how the bark produced is converted into climate-neutral thermal energy and green electricity.

Thanks to all visitors for their great interest and personal dialogue.

Website: Langer Tag der Energie

Photos: Lukanz, Spanblöchl

Solar power from photovoltaic systems drives green production

Sustainability is our principle, which is why we use solar power for our plants in Leoben, Gaishorn, Reuthe, Paskov, Wismar and Olsberg. For a greener future, Mayr-Melnhof Holz has invested a total of 13 million euros in the supply of electricity and heat from solar energy at these locations.

In Gaishorn, 10,836 panels with a total output of 4,117.68 kilowatt peak were installed on several production halls and warehouses. Thanks to this smart energy solution on the roofs of our halls, production is efficient and environmentally friendly.

In Gaishorn, Mayr-Melnhof Holz produces MM crosslam cross laminated timber, MM masterline glulam, MM profideck glulam ceilings and MM vistaline duo/trio beams.

The site currently employs 265 people.

Facts overview photovoltaic system MM Holz Gaishorn:

Number of panels | 10.836 |

Output | 4.117,68 KWp |

Installation period | 7 months |

Commissioning | Ocotber 2023 |

Photos: © Emanuel Greimler

100 Years of Bergkvist Siljan – A Century of Timber Expertise in Sweden

Insjön/Dalarna, June 2025 – Swedish heritage company Bergkvist Siljan is celebrating its 100th anniversary this year. Founded in 1925 by Axel Bergkvist with initial capital of SEK 30,000, the company has evolved into a modern and internationally successful sawmill group. Since 2022, Bergkvist Siljan has been part of the Austrian Mayr-Melnhof Holz Group.

“We are proud to have Bergkvist Siljan as part of our group. This long-established family business enriches us – particularly in the Scandinavian markets – not only with its deep-rooted expertise, but also through its strong regional ties and a corporate culture focused on long-term partnerships. We are proud of the first 100 years and look forward to many more successful decades,” says Richard Stralz, CEO of Mayr-Melnhof Holz Holding AG.

Today, Bergkvist Siljan operates three specialised production facilities in the Dalarna region: the Insjön site focuses on spruce products, while Mora specialises in high-quality pine, and Blyberg primarily processes small-dimension timber. Despite its international orientation – including a sales office in Shanghai and strong export markets such as Japan, China and South Korea – the company remains deeply rooted in its local region.

“A century is a long time, but when compared with the trees we process or the houses built with our timber, it becomes relative,” says Niklas Båtelsson, CEO of Bergkvist Siljan. “Our anniversary is part of a long story and also a sign of our confidence in the future.”

Today, the Bergkvist family remains actively involved in the company, with Per-Ragnar Bergkvist representing the fourth generation. Ulf Bergkvist, from the third generation, serves as Senior Advisor. The entrepreneurial spirit of the founding family continues to live on – both in leadership and in close relationships with employees and forest owners, many of whom have worked with Bergkvist Siljan for generations.

Anniversary celebrations are taking place throughout the year, including a summer party for all staff, attended by Mayr-Melnhof Holz owner Franz Mayr-Melnhof-Saurau, who will address the Bergkvist Siljan team. In addition, an open day will be held at the Insjön sawmill site on June 5th, featuring guided tours, exhibitions, photographs from 100 years of company history, and speeches – open to forest owners and the wider public.

Further information at: www.bergkvistsiljan.com

3000 years of wood knowledge: Kuchl graduates meet at MM Holz in Leoben

Over 100 graduates of the Kuchl Wood Technology Centre took part in this year's excursion organised by the alumni association. They visited Mayr-Melnhof Holz in Leoben.

Everyone was amazed by the sum of years of experience and the concentrated wood knowledge that was present in one place at the same time: "Added together, there are now around 3000 years of experience here," CEO Richard Stralz summarised impressively during his opening speech.

CEO Richard Stralz and the Chairman of the Alumni Association, Hubert Burböck, welcomed the graduates.

The guides from MM Holz, themselves Kuchl graduates, led a total of six groups around the log yard, through the sawmill, the planing and re-sorting plant and the newly built cross-laminated timber plant: Franz Schwarzauger, Stefan Hochfellner, Stefan Hübler, Sebastian Knoflach, Viktoria Hoffelner, Markus Haberknapp, Daniel Pichorner, Stefan Wolfger, Florian de Monte, Rudolf Angeringer and Gustav Lukanz. Andreas Hafenscherer, a graduate of the forestry school in Bruck, joined the team of guides. A big thank you also goes to Petra Leitner and Sonja Hiebler-Liebminger for the excellent organisation.

During the lunch that followed, there was a lot of networking and shop talk before we continued on to the Gösseum, the museum of the Göss brewery, and then to the Annual General Meeting in the "zum Schwarzen Hund" wine arbour. At the Annual General Meeting, Matthäus Schaffer was newly elected to the board team as youth representative. We would like to thank Ruth Roitinger, who has held this position. The actions of the Board of Directors were approved and they were entrusted with the management of the organisation for a further period as part of the new election.

Subsequently, various perspectives on the market situation were presented during the market talks - from logs and sawn timber to processed products, discussions continued into the early hours of the morning.

The AV Board around President Hubert Burböck and Managing Director Johanna Kanzian are also more than satisfied. "Never before in the history of the alumni association have we had such a high level of participation - above all, it was once again confirmed to us that such activities are more than an enrichment for young and not-so-young graduates," summarised Burböck. The network within the generations, between different processing areas and the direct information channel to Holztechnikum Kuchl is immensely important. "And that's exactly what we see as our task: to act as a link between graduates, Holztechnikum Kuchl and the companies," emphasised Kanzian.

This event once again showed how lively the Kuchl network is - characterised by mutual respect, professional curiosity and cohesion. It proves to be a platform for knowledge transfer, professional exchange and personal solidarity across generations. The youngest participant was 19 years old and the oldest 87 years old.

Planning for the 2026 AV trip is already underway - it is expected to take the members of the association to Germany.

Photos: © MMHolz

NEW: Update MM profideck brochure

The brochure is a valuable document for planners, architects and builders on all aspects of glulam ceilings from Mayr-Melnhof Holz.

The brochure contains technical data, details of the product range, helpful installation instructions and information on possible ceiling structures and spans.

MM profideck is available in German, English, French, Italian and Spanish.

To the brochure: MM profideck

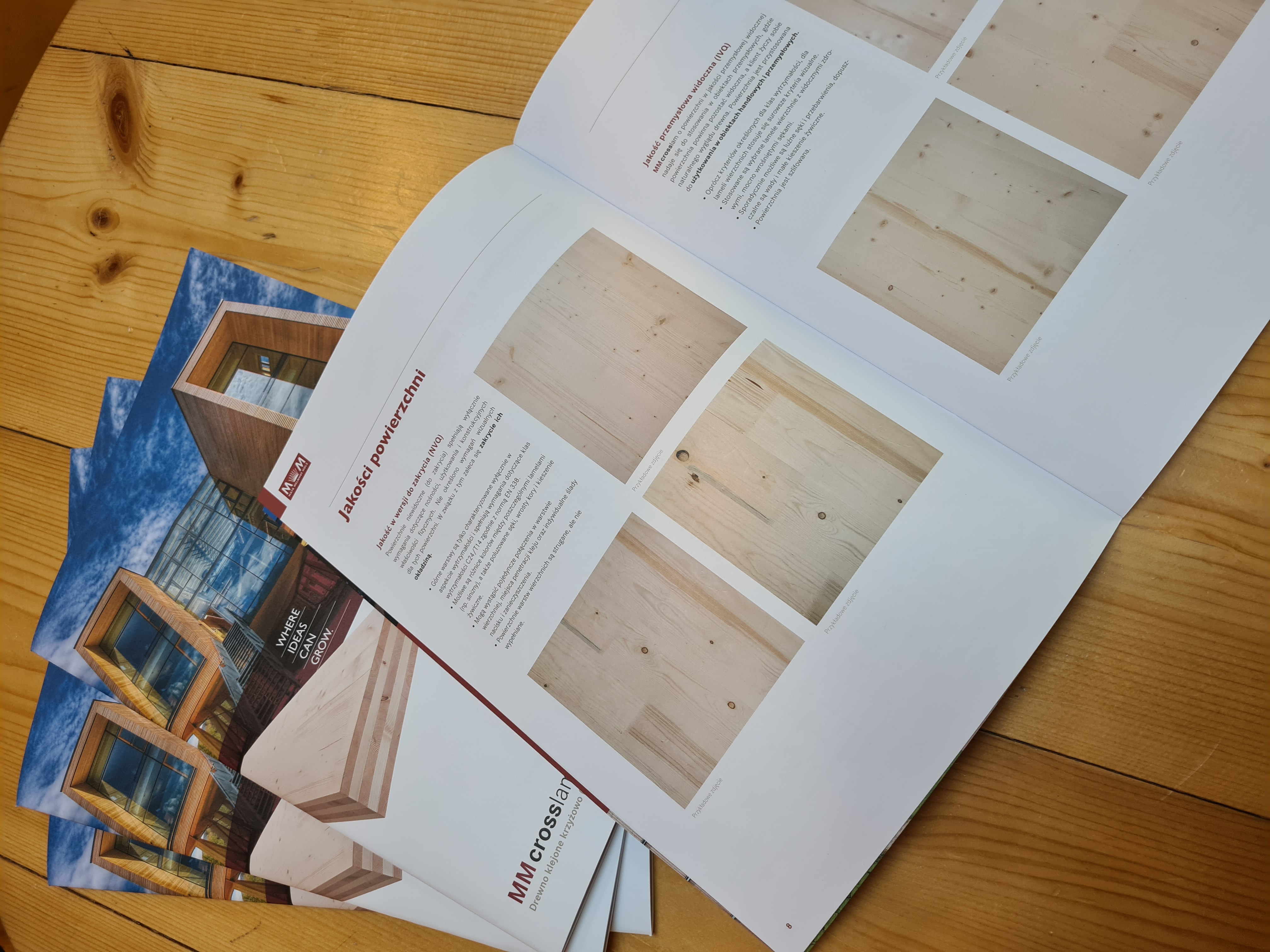

NEW: MM crosslam brochure also available in Polish

The brochure is a valuable document for planners, architects and builders on the solid wood construction material cross laminated timber from Mayr-Melnhof Holz.

The brochure MM crosslam contains technical data, information on the product range, joinery, a component catalogue, detailed pre-dimensioning tables and assembly instructions and is available in German, English, French, Spanish, Italian and now also in Polish.

To the brochure: MM crosslam

Green energy of the future: green electricity from photovoltaics

Sustainability is our principle, which is why we use solar power for our plants in Leoben, Gaishorn, Reuthe, Paskov, Wismar and Olsberg. Mayr-Melnhof Holz is investing around 13 million euros in an ecological power supply for a greener future at the sites. Step by step, the plants are now going into operation.

Our site in Olsberg is ready after an installation period of around 8 months. 3,207 panels with a total output of 1,218.66 kilowatt peak were installed on the roofs of various production halls and warehouses to supply the plant with green electricity and heat.

With the help of the new photovoltaic system, we are making a contribution to climate protection through ecological energy generation.

With MM complete Ingenieurholzbau & Gesamtlösungen by Hüttemann, MM Holz Olsberg offers a comprehensive service portfolio with our entire product range, from the initial idea to the finished timber construction.

In Olsberg, we produce MM masterline glulam, MM masterline special components up to 56 metres long and block-glued columns and beams.

The site currently employs 100 people.

Fact overview photovoltaic system MM Holz Olsberg:

| Number of panels | 3.207 |

| Output | 1.218,66 kWp |

| Installation period | 8 months |

| Commissioning | September 2024 |

Pictures: Markus Dinkel

"Timber construction and technical development" - University course TU Graz

The course focuses on specialist knowledge of wood protection measures, dealing with the special physical properties of timber constructions and the technical development of timber constructions, as well as current and sustainable design strategies such as resilient building and construction and the recyclability of timber constructions.

The course is aimed at managers and specialists in the construction sector who want to further their education and position themselves in the field of timber construction. It is aimed in particular at those in the profession:

- Architects

- Civil engineers

- Master builders

- Master carpenters

The university course consists of 3 modules of 5 ECTS each:

- Module: Sustainable timber construction (timber protection measures, resilient timber construction - durable construction, recyclable timber construction)

- Module: Building physics and fire protection in timber construction (building physics in timber construction, fire behaviour of components and fire protection in timber construction, compensation measures)

- Module: Technical finishing (technical finishing in/with timber constructions, layer separation with regard to service life, interaction between building typology and building technology)

The closing date for applications is 13 December 2024.

More information:https://www.tugraz.at/studium/studienangebot/universitaere-weiterbildung/kurse-und-seminare/holzkonstruktion-und-technischer-ausbau

Stars of Styria

Outstanding achievements in training and the award as a top training company: Mayr-Melnhof Holz Leoben celebrates success on several levels.

After three intensive years of training, Florian Moder has completed his apprenticeship as a metal technician with outstanding results.

He not only successfully passed his final apprenticeship examination, but was also recognised for his outstanding achievements with an award.

Florian proudly accepted his trophy and certificate at the ‘Stars of Styria’ event organised by the Chamber of Commerce (WKO).

The entire Mayr-Melnhof Holz team congratulates Florian on this great success and is delighted to now have him as a valuable skilled worker in the maintenance team at the Leoben site.

There is also another reason to celebrate: Mayr-Melnhof Holz has once again been recognised as an ‘Excellent Training Company’. We are proud to be part of such a successful training programme and to offer young talents a future-oriented perspective.

Honoured as a training company

Our site in Wismar was once again honoured this year by the Schwerin Chamber of Industry and Commerce as an ‘Excellent Training Company’.

The award recognises the company's commitment to dual vocational training.

Special praise goes to the trainers, who are currently supporting four young employees during their training with great passion and expertise. They ensure that the junior employees receive optimal support not only professionally but also personally on their way to becoming qualified skilled workers.

The following apprenticeships are offered at Mayr-Melnhof Holz in Wismar:

→ Electronics technician for industrial engineering

→ Industrial mechanic

→ Woodworking mechanic

Interested parties can find out more about the wide range of training and career opportunities at Mayr-Melnhof Holz here: https://jobs.mm-holz.com/Jobs

Photovoltaics as the key to a sustainable energy supply

Mayr-Melnhof Holz is also taking a big step towards a more sustainable and environmentally friendly production at its site in Wismar. The new photovoltaic system with a peak output of 2,660 kilowatt is now generating green energy.

For a greener future, Mayr-Melnhof Holz is investing around 13 million euros in ecological power supply using photovoltaic systems at its sites in Austria, Germany and the Czech Republic. The systems are gradually being put into operation at all locations. By utilising our photovoltaic systems, we are ensuring a sustainable and stable energy supply that is not dependent on the availability of fossil fuels.

The site in Wismar is ready after an installation period of around 5 months. A total of 6,998 panels with a total output of 2,659.24 kilowatt peak were installed on the roofs of various production halls and warehouses for the ecological supply of electricity and heat. Most of the power generated is used for on-site consumption; at full capacity in summer, 10 to 15 % can be fed into the public grid.

In Wismar, Mayr-Melnhof Holz produces MM masterline glulam, MM HBE solid timber construction elements, MM blockdeck glulam floorboards, MM profideck glulam ceilings and MM vistaline duo/trio beams.

The site currently employs 175 people.

Facts overview photovoltaic system MM Holz Wismar:

| Number of panels | 6,998 |

| Output | 2,659,24 KWp |

| Installation period | 5 months |

| Commissioning | August 2024 |

© Skanska

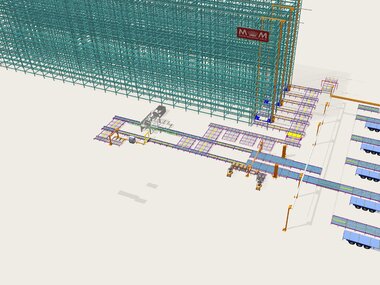

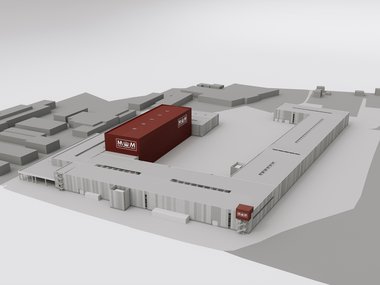

High-bay warehouse with customised conveyor technology

Mayr-Melnhof Holz has invested in a state-of-the-art, 3-aisle high-bay warehouse at its Leoben site. The major project sets a new standard for timber logistics with a high degree of automation including lorry loading.

A modern, future-orientated intralogistics solution has been created at the sawmill site in Leoben, with an automated, 3-aisle high-bay warehouse and the connecting conveyor technology for order-related sequencing, packaging, stacking and tour-orientated provision. The lorry loading in the loading hall is connected, which is also semi-automatic for the first time. The project is groundbreaking.

HÖRMANN Intralogistics was commissioned to develop a customised solution for the storage of sawn timber, lorry loading and sawn timber supply to the cross laminated timber production facility, which is both efficient and future-oriented, as part of the new construction of the high-tech cross laminated timber plant with an upstream high-performance re-sorting and planing mill. The conveyor technology transports the timber packages from the sorting and planing mill to the high-bay warehouse. These load units consist of bundled packages of sawn timber measuring up to 5.2 metres long, 1.27 metres wide and 1.30 metres high and weighing up to 3,200 kg. To transport the packages safely and gently, HÖRMANN Intralogistics relies on innovative modular belt conveyor technology.

In the 3-aisle high-bay warehouse, the timber packages, which come directly from the post-sorting and planing plant after the sawmill, are temporarily stored and, depending on the order, either loaded onto lorries for internal and external customers or removed for further processing in the cross laminated timber plant.

Stefan Hierzenberger, Head of Group Logistics at Mayr-Melnhof Holz: "The all-in-one concept from HÖRMANN Intralogistics has enabled us to revolutionise our logistics processes. The designed software control, sensor technology, innovative conveyor technology and seamless integration into our existing processes increase our efficiency and competitiveness. We are delighted with the possibilities offered by this new system."

Solar power for BSP plant

With a 3,800 kilowatt-peak photovoltaic system, the Leoben site is taking another step towards an ecological energy supply for the new high-tech cross laminated timber plant and setting the next milestone in the company's sustainable development.

Mayr-Melnhof Holz is investing around 13 million euros in an ecological power supply for a greener future at the sites in Leoben, Gaishorn, Reuthe, Wismar, Olsberg und Paskov. Step by step, new photovoltaic systems are being put into operation, and after Reuthe, electricity is now also being generated with solar energy in Leoben.

After an assembly time of around 10 months, the system is now ready for installation on the three roofs of the production halls of the cross laminated timber plant, on the roof of the high-performance re-sorting and planing plant and on the high-bay warehouse. A total of 10,000 panels, with a total output of 3,800 KWp were installed.

The power generated is used in the cross laminated timber plant; surplus energy is fed into the plant's own ring network and, if required, supplies the rest of the site, where a biomass power plant with 4 boilers is also operated and the electricity from two hydropower plants in the Göss ditch is used exclusively for the site.

Mayr-Melnhof Holz produces cross laminated timber MM crosslam, sawn timber and pellets in Leoben.

The site currently employs 350 people.

Facts overview photovoltaic system MM Holz Leoben:

| Number of panels | 10,000 |

| Output | 3,800 KWp |

| Installation period | 10 months |

| Commissioning | July 2024 |

Pictures: Haberknapp, Hiebler-Liebminger

Cheers to 20 years of Mayr-Melnhof Holz Paskov s.r.o.

From a greenfield site to the largest sawmill in the Czech Republic: production at Mayr-Melnhof Holz's Czech sawmill site in Paskov started in 2004, just 8 months after construction began. The 20th anniversary was duly celebrated on 21 June 2024.

The largest sawmill in the Czech Republic celebrates its anniversary

Mayr-Melnhof Holz Paskov s.r.o. is the largest sawmill in the Czech Republic with a cutting capacity of around 1.45 million solid cubic metres of softwood logs and a production capacity of 100,000 tonnes of pellets per year. It is located in the north-east of the country, in Staříč, was commissioned in 2004 as the country's most modern sawmill and is one of five sawmills belonging to the Austrian Mayr-Melnhof Holz Group.

Paskov marked the first step in the internationalization of the Mayr-Melnhof Holz Group.

Franz Mayr-Melnhof-Saurau, owner: "The decision in 2002 to build a sawmill in the Frýdek-Místek region was a courageous step and turned out to be a valuable asset: the Czech Republic welcomed us with open arms and showed itself to be a proud industrial nation. The sawmill went into production in 2004, just 8 months after construction began. Over the past 20 years, the company has proven to be stable and efficient. This sawmill stands for quality, reliability, innovation and a strong team spirit among the employees."

The owner's invitation to celebrate the company's 20th anniversary was accepted by numerous guests of honour from politics, business, science and interest groups, business partners, as well as the Supervisory Board, the Management Board and the management team of Mayr-Melnhof Holz and several pioneering guests of honour, people from the very beginning and the development of the company, including the sawmill's long-time managing director, Marie Wagnerová, who managed the plant for 18 years until her retirement in 2021.

The successful Mayr-Melnhof Holz Paskov team - the employees under the leadership of the two managing directors, Michal Kocián and Lukáš Konečný, were given a special place at the ceremony.

The keys to success

Michal Kocián and Lukáš Konečný, who hosted the official ceremony, thanked the employees: "You are this company and carry it through good and challenging times to success. A great team."

Richard Stralz, CEO of Mayr-Melnhof Holz Holding AG and Chairman of the Management Board: "I am proud of this joint achievement by our employees. Their commitment and passion are the keys to our success, thanks to them we have been able to develop into one of the leading companies in the industry. May the next twenty years be just as successful and fulfilling as the past."

Where ideas can grow

Inspired by the Group's motto - "Where ideas can grow." - and accompanied by best wishes for the company, the employees and the management, owner Franz Mayr-Melnhof-Saurau together with Managing Directors Michal Kocián and Lukáš Konečný planted a spruce tree. The wishes for a prosperous future for the sawmill were warmly echoed by the new Chairman of the Supervisory Board Franz Rotter and the members of the Supervisory Board as well as the Management Board Richard Stralz (CEO), Michael Wolfram (CFO) and Arnulf Penker (CTO).

The official celebration was accompanied by various activities for the guests. A factory tour was held at the beginning, in addition to a photo exhibition about the last 20 years of company history, there were nail sticks, visitors could prove their skills by hammering in nails, teamwork was required when cutting logs to length with a traditional cross-cut saw, "Flying Saws" fascinated with a sawing demonstration and the band entertained with lively songs.

The unanimous feedback: A successful anniversary celebration! Cheers to Mayr-Melnhof Holz Paskov and all the best for the next 20 years.

Guests of honour:

- Helena Pešatová, Senator of the Czech Republic

- Petr Korc, Mayor of Frýdek-Místek

- Libor Alex, Mayor of Staříč

- Petr Baďura, Mayor of Paskov

- Petra Cetin, CzechInvest

- Vladimír Gryce, Director of the Mendel University Institute in Brno

- Libor Jankovský, Dean of the Faculty of Forestry and Wood Technology at Mendel University in Brno

- Pavel Bednář, Research Institute of Forestry and Hunting

- Jiří Kubala, Deputy of Mayor Libor Alex - Staříč

- Marie Wagnerová, former Managing Director Mayr-Melnhof Holz Paskov s.r.o.

- Petra Votavová, UniCredit Bank Czech Republic and Slovakia, a.s

About Mayr-Melnhof Holz Paskov

The company currently employs 250 people. The sawmill processes spruce logs from sustainably managed forests, primarily from the surrounding, timber-rich regions. The cutting capacity is 1.45 million solid cubic metres. Sawn timber is produced for the sister plants in Austria and Germany for the manufacture of cross-laminated timber and glulam and for customers, primarily in Central Europe and Japan, with smaller quantities going to North Africa, the Middle East and overseas. Pellets have been produced since 2007, with a production capacity of 100,000 tonnes/year. The wood chips produced in the sawing process are delivered on-line to the neighbouring Lenzing Paskov pulp plant, a company of the Lenzing Group. The plant's own biomass power station with an installed capacity of 32 megawatts supplies the sawmill, the drying chambers and the pelletisation with thermal energy. Mayr-Melnhof Holz Paskov is PEFC-certified.

Facts Mayr-Melnof Holz Paskov s.r.o.

Location in | Staříč, Fridek-Mistek region (north-east of the Czech Republic) |

Total area | 375.000 m² |

Production area | 270.000 m² |

Building decision | 2002 |

Start of construction | April 2003 |

Sawmill commissioning | 2004 October 2003: First log delivery November 2003: Start of log sorting December 2003: First cut during trial operation January 2004: Production 07th May 2004: Official opening ceremony |

Construction time | 8 months |

Investment | 60 million euros |

Pelletisation commissioning | 2007 (First production 06th February 2007) |

Employees 2023 | 250 |

Products | Sawn timber, pellets, wood chips |

Cutting capacity | 1.45 million solid cubic metres |

Record cut in 2019 | 1,465,473 solid cubic metres |

Wet storage | Since 2020: 1.4 hectares for up to 60,000 solid cubic metres Sprinkling since August 2022 (previously used as pre-storage without sprinkle) |

Target markets sawn timber | Intercompany for the sister companies (CLT/glulam production), Central Europe, Japan; partly North Africa, Middle East, overseas |

Pellet production capacity | 100,000 tonnes |

Biomass power plant | 3 boiler systems 32 megawatts total output (heat for drying chambers, pelletising, sawmill) |

Extension to administration building | 09th November 2022: Opening |

Photocredit: © Juriček Radek

Langer Tag der Energie – Mayr-Melnhof Holz Leoben öffnete seine Türen

Am langen Tag der Energie, der am 22. Juni 2024 in der ganzen Steiermark stattfand, lud Mayr-Melnhof Holz ein, einen Blick hinter die Kulissen zu werfen. Interessierte Besucher*innen hatten die Möglichkeit, die Pelletierung und das Biomasseheizkraftwerk am Standort in Leoben zu besichtigen.

Nachhaltiges Handeln liegt uns am Herzen, der wertvolle Rohstoff Holz wird zu 100 Prozent verwendet. Die Schnittholzproduktion ist eine sogenannte Kuppelproduktion. Produziertes Schnittholz wird frisch, trocken, ungehobelt oder gehobelt zur Herstellung von Holzbauprodukten an unsere Weiterverarbeitungswerke oder externe Kund*innen geliefert.

Die dabei anfallenden Säge- und Hobelspäne sind kein Abfall, sondern wertvoller Rohstoff für das ökologische Heizmaterial Pellets. Diese werden in den Pelletierungen, die wir an allen Sägewerkstandorten betreiben, hergestellt.

Die Hackschnitzel finden in der nächstgelegenen Papier – und Zellstoffindustrie Verwendung. Ein wichtiger Teil des Rohstoffs, ist auch die anfallende Rinde, welche in den Biomasseheizkraft-

werken an allen Sägewerksstandorten in klimaneutrale Wärmeenergie und auch Ökostrom umgewandelt wird.

Danke an alle Interessierten für den Besuch und den persönlichen Austausch.

Website Langer Tag der Energie: Langer Tag der Energie

Ecological power supply with photovoltaics

Sustainability is our principle, which is why we use solar power for our plants in Leoben, Gaishorn, Reuthe, Paskov, Wismar and Olsberg. Mayr-Melnhof Holz is investing 13 million euros in an ecological power supply for a greener future. The plants are now being put into operation step by step.

After an installation period of around 7 months, the location Reuthe (Vorarlberg) is now ready. A total of 4,780 panels were installed on the production and storage halls, which are now generating green electricity for the company's own consumption. The output totals 1,808.80 KWp and is a further step towards an environmentally friendly and sustainable production.

In Reuthe, Mayr-Melnhof Holz produces glulam MM masterline, glulam special components and formwork products.

220 people are employed at the location.

Fact overview photovoltaic system MM Holz Reuthe:

Location | Mayr-Melnhof Holz Reuthe |

| Number of panels | 4,780 |

| Output | 1,808.80 KWp |

Installation period | 7 months |

Commissioning | May 2024 |

Photos: Mathias Simma

Fully automatic high-frequency press for glulam in operation

Mayr-Melnhof Holz invests in a fully automated modern high-frequency press for the production of glulam standard components at its Olsberg site.

With the new pressing system, Olsberg is making a qualitative leap in the automated processing of production orders and is at the cutting edge of technology to provide the straight components required for the glulam standard business.

The high-frequency plant presses glulam elements with maximum dimensions of 29 cm x 130 cm x 24.20 m and replaces two hydraulic presses that were in need of repair. The space-saving implementation made it possible to additionally integrate a constructive press bed for glulam up to 25 m in length into the production process.

As a system provider, ABF was commissioned to integrate the new press in terms of control technology. The focus was on the communication of the high-frequency press with the ERP system, the glue application and the conveyor lines as well as the control of the fully automatic labeling of the pressed glulam bars and the automatic collection of production data to increase productivity.

The investment project is part of the Mayr-Melnhof Holz Group's optimization, automation and digitalization strategy.

© Weiss-Moser

‘Fundamentals of timber construction’ - University course TU Graz

‘Expanding technical knowledge in the use of wood as a building material and gaining expertise in contemporary timber architecture’ are the aims of this part-time course at Graz University of Technology, which consists of 3 modules (5 ECTS each) and lasts approx. 10 weeks.

The course is aimed at managers and specialists in the construction sector who want to further their education and position themselves in the field of timber construction. The course is aimed in particular at

- Architects

- Civil engineers

- Planning master builders

- Master carpenters

The course consists of 3 modules:

- Module: Wood as a building material (wood as a resource, properties, materials, types of wood, design differences to other materials)

- Module: Timber construction methods and load-bearing systems (historical and modern timber construction methods and load-bearing systems, structural design, modelling and tectonics)

- Module: Construction with wood (resilient constructions and superstructures, polyfunctionality, prefabrication and joinery, system and modular construction, based on multi-storey structures of common building typologies)

Application deadline is September 20, 2024.

More information: Grundlagen Holzbau - TU Graz

Cross laminated timber: Manufacturer-specific environmental product declaration (EPD)

Mayr-Melnhof Holz is continuously committed to improving products and production processes, also in order to further reduce environmental impact and thus help shape a sustainable future. A manufacturer-specific environmental product declaration (EPD) in accordance with ISO 14025 and EN 15804+A2 has now been issued for MM crosslam cross laminated timber.

At Mayr-Melnhof Holz, we are proud to manufacture and offer products that are not only of high quality, but also make a positive contribution to protecting our environment and climate. We are convinced that sustainability, environmental and climate protection are key values for the future of our planet. In order to offer our customers and partners maximum transparency, we regularly subject our timber construction products to a thorough environmental assessment by an independent external testing body. A manufacturer-specific environmental product declaration (EPD) has now even been created for MM crosslam cross laminated timber. This EPD provides detailed information on the environmental impact over the entire life cycle of the product.

Facts

ENVIRONMENTAL PRODUCT DECLARATION according to ISO 14025 and EN 15804+A2 for

cross laminated timber MM crosslam.

Declaration holder: Mayr-Melnhof Holz Holding AG

Publisher: Institut Bauen und Umwelt e.V. (IBU)

Program owner: Institut Bauen und Umwelt e.V. (IBU)

Declaration number: EPD-MAY-20240070-IBA1-DE

https://www.mm-holz.com/en/service/technical-documents

Do you have any questions about the EPD or our products?

Our team will be happy to answer your questions and help you choose the right products.

Neue Broschüre zu Bauen & Sanieren mit Holz

Der regionale Ratgeber zum Thema „Sanieren und Erweitern mit Holz für eine klimafitte Zukunft“ ist nun verfügbar. Die Broschüre wurde im Rahmen des Projekts KLAR! Murraum Leoben in Kooperation mit dem Holzcluster Steiermark und proHolz Steiermark erstellt.

Richard Stralz, CEO Mayr-Melnhof Holz, anlässlich der Präsentation der Broschüre am 19. März im Rathaus Leoben:

Wir haben in den vergangenen 10 bis 20 Jahren eine steigende Nachfrage im Zuge der Klima- und Ressourcenwende und damit eine echte Renaissance des Werkstoffs erlebt. Heute arbeitet man im Gebäudebau, bei Sanierungen und Aufstockungen mit Massivholz in Form von Brettschichtholz und Brettsperrholz, Holz findet aber auch als Bauholz und Furnierholz Einsatz. Es ist nicht nur ein leicht zu bearbeitender Werkstoff, er ist auch nachwachsend und regional verfügbar. Alle 4 Sekunden wächst in der Steiermark das Holz für ein Einfamilienhaus nach. Wir tun hierzulande mit Herz und Verstand sogar mehr, als das Prinzip der Nachhaltigkeit fordert, welches seit mehr als 300 Jahren unsere Waldwirtschaft prägt: Es wächst mehr nach, als geerntet wird. Holz haben wir genug, das ist die schöne Nachricht.

Die Nutzung von Holz ist zudem ein wichtiger Teil der Lösung bei der Bewältigung des Klimaproblems. Man darf nicht vergessen: Ein Kubikmeter Holz bindet eine Tonne CO2 – als Baum wie als Holzmöbel, Holzfenster, als Holzgebäude oder auch Holzspielzeug.

Holznutzung schafft also einen zweiten Wald aus Holzprodukten, da der Kohlenstoff im verarbeiteten Material gespeichert bleibt. Gleichzeitig wächst durch die Aufforstung ein neuer Wald nach, in dem wiederum Kohlenstoff gespeichert und Sauerstoff an die Umgebung abgegeben wird. Dazu kommt der wichtige Substitutionseffekt: Holz ersetzt andere CO2-intensive, nicht-nachwachsende Materialien und vermeidet dadurch deren CO2-Emissionen bei der Herstellung. Hier liegt der größte Hebel für den Klimaschutz: Die in Österreich aus österreichischem Holz hergestellten Produkte ersparen pro Jahr rund acht Millionen Tonnen CO2, das entspricht etwa einem Zehntel der gesamten Treibhausgasemissionen Österreichs in einem Jahr.

Holz ist als Werkstoff und Baumaterial unschlagbar in seiner CO2-Bilanz. Und das gilt es auch zu nutzen, für unsere Zukunft und die unserer Kinder und Enkelkinder.

Wir sind in der glücklichen Lage, dass hier in der Region die Beteiligten entlang der gesamten Wertschöpfungskette Holz für den Holzbau sehr nahe beieinander liegen: nachhaltig bewirtschaftete Wälder, Forstwirte, Sägewerke, Holzverarbeitungsunternehmen, Holzbauunternehmen. Alle sind wichtige Arbeitsfelder und Arbeitgeber, im Zusammenwirken und durch mutige Investitionen entsteht der Erfolg. So haben wir uns auch entschlossen, hier am Standort im Anschluss an unser Traditionssägewerk um rund 175 Millionen Euro ein Hightech-Brettsperrholzwerk zu errichten, in dem wir zukünftig im Vollbetrieb bis zu 130.00 m3 Brettsperrholz dem Markt zu Verfügung stellen können. Die neue Fabrik haben wir der mayr-melnhof‘schen Nachhaltigkeitsstrategie folgend natürlich in Holzbauweise errichtet, sie ist ein Vorzeigeobjekt, weltweit der erste PEFC-zertifizierte Industriehallenkomplex dieser Größenordnung mit rund 33.000 m2 Produktionsfläche.

Die Broschüre „Sanieren und Erweitern mit Holz“ beleuchtet den modernen Holzbau, die Vorteile wie Vorurteile der Holzbauweise und gibt den Leserinnen und Lesern einen Überblick über etablierte Einsatzbereiche sowie Konstruktionsweisen. Gelungene regionale Best-Practice-Beispiele untermauern die Argumente und sind eine Quelle für Inspiration.

Die Broschüre ist ab sofort auf der Gemeinde Leoben, im Büro der KLAR! Murraum Leoben, sowie unter https://www.murraum-leoben.at/downloads kostenlos erhältlich.

From forest cottage to town house

The children at the Andersengasse kindergarten in Graz now have a sustainable, ecological meeting, play and feel-good house made of cross-laminated timber, giving them a little piece of the second forest in their playground.

Mayr-Melnhof Holz, Mayr-Melnhof-Saurau Forstbetrieb and Strobl Holzbau handed over the "Waldhäusl" to the kindergarten on 14 March.

From forest cottage to town house

The smart little house made of the future building material cross laminated timber, which we call the "Waldhäusl", is a success story of regional, sustainable value creation and partnership-based cooperation.

In 2023, the idea of Mayr-Melnhof-Saurau Forstbetrieb and Mayr-Melnhof Holz Holding AG was realised in cooperation with Nussmüller Architekten ZT GmbH and Strobl Bau - Holzbau GmbH. Its history is fit for the future:

- Planted many decades ago in the Styrian forests of the Mayr-Melnhof forest, the local spruce trees for the "Waldhäusl" were responsibly tended and finally harvested.

- Creative minds from the Nussmüller architecture studio contributed their wealth of experience and drew the "Waldhäusl" in three dimensions using modern CAD programmes. This allowed us to visualise it for the first time.

- Mayr-Melnhof Holz took over the digital data, transferred it to the ultra-modern CNC controls of the fully automated joinery systems and produced the cross laminated timber required for the "Waldhäusl" with millimetre precision.

- The excellently trained carpenters from Strobl Holzbau took their tools to heart, put the individual parts together professionally, assembled the building elements for this "Waldhäusl" with passion, gave it a weatherproof roof and walls made of natural shingles.

- Children fill the "Waldhäusl", which has now become a "Stadthäusl", with laughter, play and joy. Mayr-Melnhof Holz, Mayr-Melnhof-Saurau Forstbetrieb and Strobl Holzbau donated the little house to the Andersengasse kindergarten in Graz.

Fashion show stage, presentation room, meeting house & venue

In 2023, the Waldhäuschen was used for the first time at the forest festival on Graz's main square, where it served as a stage for a fashion show. The next stop was the open day to mark the opening of Mayr-Melnhof Holz's high-tech cross-laminated timber plant in Leoben. As a space and object, it presented to the guests what is possible with wood as a building material and the feel-good atmosphere that is inherent in wooden houses. At the Stadt-Land-Fest festival on Leoben's main square, it delighted the public not only as a stage for the band. The children of the Andersengasse kindergarten will now use the Waldhäuschen town house as a place to meet, retreat and play.

Sustainability makes sense: wooden houses make a second forest

Sustainability is anchored in the Waldhäuschen-Stadthäuschen in many ways. Even the youngest children can easily understand what the more than 300-year-old term actually means and why sustainability is based on three pillars: ecological, economic and social:

Wood from a forest that has been sustainably managed for generations in the immediate vicinity is a valuable, renewable raw material: trees are harvested and new trees are planted that bind the harmful greenhouse gas CO2 and release the oxygen that is essential for life. 1 m3 of wood stores around 1 tonne of CO2 . Only as much is taken from the forest as grows back: the principle of sustainability! In Styria, for example, the wood for a detached house grows back every 4 minutes. Short transport routes lead to the nearby sawmill, which produces the sawn timber that is later needed for the production of cross-laminated timber, among other things. The cross laminated timber production adjacent to the sawmill: here the sawn timber lamellas are carefully sorted and glued together crosswise to form dimensionally stable cross laminated timber panels. Delivered to the timber construction company ready for assembly on site or project-specifically bound, the cross laminated timber panels are used as walls and ceilings in both modern and traditional timber construction. The carbon stored by the trees remains stored in the building components throughout their entire service life. In this way, timber houses become a second forest and make an indispensable contribution to the fight against climate change, for us and for the future of our children and grandchildren.

Great joy among the children

The children at Andersengasse kindergarten in Graz are delighted. Now they have their own little wooden house and a piece of a second forest in their playground!

City Councillor for Education Kurt Hohensinner, City of Graz: "The future of our country is growing up in our kindergartens, just as the sustainable material of the future, wood, is growing up in the forests. It is therefore a perfect fit that the forest house in the Andersengasse kindergarten has found a good and suitable location for the future. A big thank you to those responsible at Mayr-Melnhof Holz und Forst for putting this fantastic showcase project together."

Richard Stralz, CEO of Mayr-Melnhof Holz Holding AG: "This project is a wonderful example of sustainability: the subsequent use after the "exhibition trip" was already taken into account during the planning phase, thus ensuring that this little house will remain as a second forest that binds carbon for decades to come."

Willibald Ehrenhöfer, Forest Director Mayr-Melnhof-Saurau Forstbetrieb: "Sustainable action starts small ... - Children are the future of our society, and small trees are the future of our forest. It takes love, prudent education, care, space and time for children to become stable adults. It is the same with our forests; only through careful management and use can our forests fulfil their many functions in the future. Just as there cannot only be great people, there cannot only be great old trees in a healthy forest fit for the future. The forest cottage is therefore also a symbol of intergenerational sustainable thinking and action."

Markus Kroisleitner, Head of Timber Construction at Strobl Holzbau: "Wood is probably the oldest and most versatile building material in the world and the building material of the 21st century: climate-friendly, renewable, regionally processed, with a high degree of prefabrication, which enables fast construction times, light in weight with high strength. It is ideal for a forest cottage as well as for multi-storey buildings, whether residential or commercial, as well as for renovations and redensification. After decades of use, wooden houses can simply be dismantled and the waste wood reused for furniture, for example. That is sustainable."

Co-operation partner in the Waldhäusl project:

Franz Mayr-Melnhof-Saurau forestry operation (mm-forst.at)

STROBL Bau - Holzbau GmbH | Construction company with quality

NUSSMÜLLER ARCHITEKTEN - Architecture Studio in Graz (nussmueller.at)

MM TIMBER LOG: The cycle for our future

The fact check is clear and the result is well known: Wood has the smallest ecological footprint of all building materials and binds the harmful greenhouse gas CO2 . Richard Stralz, CEO of the Mayr-Melnhof Holz Group, is convinced that we must utilise this in the fight against climate change, both for ourselves and for the future of our children.

Is our future really at stake?

Richard Stralz: Our climate has already changed and continues to change. The capricious weather conditions of recent months and years are a stark reminder of the seriousness of the situation: we need to act before it's too late. Wood is a natural partner in this endeavour - if we use it sensibly in a cascading manner and manage our forests sustainably.

Forest management plays a key role?

Of course, because only a managed forest is a climate-fit forest and can make the absolutely necessary contribution in the fight against climate change. After just a few decades in which a forest has been left to its own devices, the CO2 store of a forest becomes a net CO2 emitter caused by decay processes. Proper forest management with thinning and timely timber harvesting as well as the reforestation of harvested forest areas with the right distribution of tree species, on the other hand, secure the forest as a carbon store and oxygen producer. Young forests between 40 and 60 years of age absorb the most CO2 . This sustainable management also preserves the forest as a species-rich ecosystem.

Does sustainability in the use of wood mean a long-term approach?

That's right, and it means gradual utilisation. It is our duty to ourselves and our children and grandchildren to use our resources sensibly, sustainably and ecologically, but this applies to all natural resources. Sensible refers to the way in which a material is used and is determined by the properties of the raw material. For example, building a cellar out of wood is not sensible. In contrast, the use of cross laminated timber

as a load-bearing wall or ceiling, a support or glued laminated timber - spans of over 50 metres are possible here - makes sense. Sustainable and ecological refer to the cascading utilisation of the raw material over the longest possible service life. This means that we must always start with the highest-value use, with thermal utilisation at the very end of the cascade after decades of material use of the material in various products.

So houses made of wood are part of the solution to the climate problem?

We must bear this in mind: One cubic metre of wood binds around one tonne of CO2. Utilising wood therefore creates a second forest, as the carbon remains stored in the processed material. At the same time, new trees grow back through reforestation, which in turn store carbon and release oxygen into the environment. This is the cycle for our future. Climate-friendly construction starts with the avoidance of CO2, because the use of wood in construction has an important substitution effect: wood has excellent building physics properties and can often replace other materials that are CO2 -intensive to produce and are not renewable. I have already mentioned walls, ceilings, beams and supports. In relation to its strength, wood is very light in weight, making it ideal for urban redensification, the conversion of attics and for adding storeys, as significantly lower weights have to be absorbed by the existing building structure. The substitution of other building materials is the greatest lever for climate protection. Products manufactured in Austria from Austrian wood save around eight million tonnes of CO2 per year, which corresponds to around ten percent of Austria's total greenhouse gas emissions in one year.

Do we have enough wood available for the construction?

In Austria alone, enough wood grows every 30 seconds to build a detached house. Our forest cover has increased by 23 per cent in the last 25 years, and even more in the rest of Europe. We know that cement and steel production account for around a third of CO2 production worldwide. If we want to do something for the climate, we need to use more wood in long-lasting wood products, in the private sector but above all in the public sector, such as in kindergartens, schools, care facilities, etc., so a big appeal to politicians: better and sustainable framework conditions for the use of wood must be created now. We have enough wood, and it is available regionally.

Article published in: https://www.businessmonat.at/jaenner-2024/der-kreislauf-fuer-die-zukunft

How much “US” is in sUStainable forest management?

PEFC Austria addressed this question as part of this year's campaign.

Short videos are used to show how many steps and people it takes for a tree from sustainable forestry to end up in a final product.

The aim of the campaign was to illustrate to consumers the necessary steps, checks and tests that a product has to undergo in order to receive the seal of approval. Every single step in the value chain is strictly controlled, which means that the PEFC seal can guarantee that the products come from sustainably managed forests.

But how much US is actually in sUStainability?

Forest owners, forest workers and employees in PEFC-certified companies as well as consumers who buy products with the seal, they all symbolize the "US”. As PEFC-certified companies, Mayr-Melnhof Holz and Franz-Mayr-Melnhof Forstbetriebe are part of the campaign and provide insights into the harvesting of wood from sustainable forestry, soil-conserving transportation from the forest and resource-conserving further processing.

Mayr-Melnhof Holz is not only a pioneer in wood processing, but also in sustainable forest management. 100% of the valuable raw material wood is used. The sawdust produced during cutting is processed into an ecological, sustainable heating material.

The short video with Willibald Ehrenhöfer, Forestry Director at Franz-Mayr-Melnhof Forstbetriebe and Franz Schwarzauger, Managing Director of Mayr-Melnhof Holz Leoben, shows how the valuable heating material is produced and how many steps and people are involved in the process.

All short films can be found at https://www.pefc.at/pefc-austria/

Consciously choosing products with the PEFC seal when shopping supports forest owners and subsequently, employees in the 550 local companies that work with sustainably sourced timber products. Anyone who chooses products with the PEFC seal is not only looking after the forest, but also at local jobs along the value chain of the sustainably produced future building material wood.

Top of Styria in the production sector

On 20 November 2023, the top companies in Styria were honoured. Mayr-Melnhof Holz is one of them: Top 1 in production! The "Tops of Styria" 2023 stand for the many outstanding companies in Styria and their performance in the 2022 financial year. Entrepreneurs receive the award on behalf of their employees, who provide jobs, added value, economic growth and thus quality of life in the province with their hands, hearts and minds.

For Richard Stralz, CEO of Mayr-Melnhof Holz Holding GmbH, first place at the Tops of Styria in the prestigious "Production" category is a great honour for the commitment and performance of all employees of the Mayr-Melnhof Holz Group. At the same time, it is motivation and a mandate to continue to deliver top performance in the future and, in keeping with the shape of the trophy - it is a piece of rock from the Dachstein, the highest mountain in Styria - to keep striving for and reaching new peaks.

Mayr-Melnhof Holz is a large company with an impressive history and performance in the all-important timber industry. What drives you personally?

Richard Stralz: The employees, their hands-on mentality and, above all, their love of wood. They deserve the prize, they have delivered the performance. I am grateful to accept it on behalf of all my colleagues.

Where are you heading?

Richard Stralz: We work with the fantastic material wood and have just opened a new cross laminated timber plant in Leoben. Cross laminated timber used in construction acts like a second forest.

A "second forest" - how can we imagine that?

Richard Stralz: We all know: Wood binds CO2 for a lifetime and is therefore an important part of the solution in the fight against climate change: we know that wood is a wonderful building material for creating living space. Mayr-Melnhof Holz produces the timber construction elements for this, construction elements not only for our personal future, but also for that of our children, grandchildren and great-grandchildren - and beyond.

About the award: The annual magazine has been published since 1994 with a turnover ranking of the 100 companies with the highest turnover in Styria. In an anonymous voting process, a 300-strong jury of experts from business, industry, science and the media selects the "Tops of Styria", the best of the best in the Styrian corporate landscape.

The awards were presented this year in the Europasaal of the Styrian Chamber of Commerce by Andreas Herz, Vice President of the Styrian Chamber of Commerce; Barbara Eibinger-Miedl, Provincial Councillor for Economy, Tourism, Regions, Science and Research; and Martin Novak, Editor-in-Chief of the business magazine Top of Styria.

Arnulf Penker - Chief Technology Officer from September 1, 2023

Considering the growth of the Mayr-Melnhof Holz Group, the Supervisory Board has decided to fill the position of a CTO (Chief Technical Officer).

Mr. DI Arnulf Penker MBA will take over this important task in one of Europe's leading sawmill and wood processing groups as of September 1, 2023.

Reinhard Zellner, Chairman of the Supervisory Board: "With Mr. Penker, we have succeeded in bringing on board an expert with extensive experience in the wood processing industry. With three members - DI Richard Stralz as CEO, DI Michael Wolfram in the function of CFO and DI Penker as CTO - the Management Board team of MM Holz is extremely powerful and excellently positioned for our future strategy."

Mr. Penker is a graduate of the University of Natural Resources and Applied Life Sciences, Vienna (BOKU), majoring in wood and natural fiber technology, and holds an MBA from the Kenan-Flagler Business School, University of North Carolina, USA.

Hurray for the opening ceremony of the world's first PEFC-certified cross-laminated timber plant and The Next Generation!

On June 23, 2023, only two years after the start of construction, Mayr-Melnhof Holz Holding AG opened the high-tech cross-laminated timber production at the sawmill site in Leoben.

Franz Mayr-Melnhof Saurau, owner: "With the new cross laminated timber plant we are in line with the spirit of the times. It is our clear commitment to our responsibility for 'The Next Generation', indeed, for all future generations, because: 'The future begins today'! When constructing these buildings, it was important to us to use building materials made of wood wherever this valuable raw material can be used sensibly. We are proud that we have built the first timber construction project of this size in the world that has been PEFC-certified."

11,500 m3 PEFC-certified timber construction products from the company's own production were used. With an investment sum of 175 million euros, the BSP factory with upstream re-sorting and planning plant and a fully automated high-bay warehouse for sawn timber is the largest single investment in the history of the Mayr-Melnhof Holz Group.

Facts:

- More than 33,000 m2 of hall space was built.

- Almost 12,000 m3 PEFC-certified timber in the form of cross-laminated timber boards, glulam beams, three-layer boards and also construction timber – all from the company's own productions – were used.

- The new high-bay warehouse has 27,000 m3 of storage capacity, with room for around 7,000 sawn timber packages.

- Up to 70 trucks per day can be loaded with sawn timber from the high-bay warehouse.

- Around 140,000 m3 cross-laminated timber can be produced per year in full operation, which is more than 2,500 single-family houses per year, storing around 128,000 tonnes of CO2

- Around 11,000 tonnes of CO2 are bound in the new CLT plant itself.

- 50 new green jobs were created in the region.

- On the roof is a 3.8 megawatt peak photovoltaic system for the ecological supply of electricity and heat to the plant.

- The sawn timber supply for the cross-laminated timber production is handled by the adjacent sawmill without additional transport routes.

Richard Stralz, CEO of Mayr-Melnhof Holz Holding AG: "I am proud of this joint achievement of our employees, who have realised this impressive factory in cooperation with our suppliers."

After the completion of the construction and the ramp-up phase of production, Richard Stralz (CEO) and Michael Wolfram (CFO) handed over the responsibility for prosperous growth during the opening ceremony. In the traditional ceremony of handing over the keys, they handed over the responsibility for prosperous growth to the production managers Markus Thier (Plant Manager) and Martin Klingenbrunner (Production Manager), as well as to the sales managers Bernhard Waldner (Division Manager Sales Processed Timber Products) and Florian de Monte (Sales Manager Cross-laminated Timber).

The sawmill's Plant Manager, Dietmar Sagmeister, received the "key" for the re-sorting and planning mill as well as the lamella center, which are located directly adjacent to the traditional sawmill and are part of the Saw Division at Mayr-Melnhof Holz.

The Strobl timber construction company, which was responsible for the timber construction of the building complex, presented Franz Mayr-Melnhof-Saurau with a hand-carved Klementi, the patron saint of forestry, timber and sawmill workers, on behalf of all "Mayrischen". The work of art will be given a place of honour in the CLT factory for all to see.

At the end of the opening ceremony, the Leoben city priest Markus Plöbst blessed the carved patron saint, all the guests present, the people who work in the cross laminated timber plant, and all those who now and in the future have to do with the timber construction product cross laminated timber or live or work in buildings constructed with this future material at the cross laminated timber plant in Leoben.

Guests of Honour:

- Landesrat ÖR Johann Seitinger, representing the Governor of Styria, Christopher Drexler

- Landesrätin Mag.a Ursula Lackner, representing the Deputy Governor Anton Lang

- State Minister for Economic Affairs, MMag.a Barbara Eibinger-Miedl

- District Governor of Leoben, Mag. Markus Kraxner

- Mayor of the Municipality of Leoben, Kurt Wallner

- Parish priest of Leoben, Mag. Dr. Markus Plöbst

- President of IV Austria, Ing. Georg Knill

- President LK Steiermark, ÖR Franz Titschenbacher

- Chairwoman of the Wood Industry Section of the Styrian Chamber of Commerce, Monika Zechner

- Chairman Agriculture and Forestry, Carl Prince of Croy

- Chairman of the Austrian Forest Association, Rudolf Rosenstatter

- Chairman of the Austrian Sawmill Industry, DI Markus Schmölzer

- Federal Chairman of the Forestry Contractors in the Professional Association of Commercial Service Providers in the Austrian Federal Economic Chamber, Peter Konrad

- Chairman of proHolz Steiermark and Chairman of the Styrian Forest Association, LKR Paul Lang

- Chairman of PEFC-International, Eduardo Rojas Briales

- Chairman of PEFC-Austria, FD DI Dr. Kurt Ramskogler

- Rector of TU Graz, Univ. Prof. DI Dr. Dr. Harald Kainz

- Deputy Managing Director of IV Steiermark, Mag.a Nina Zechner

- Managing Director of SFG, Mag. Christoph Ludwig

Three major events took place during the opening:

- Official opening ceremony on June 23, 2023 with more than 550 guests,

- Summer party for employees at the Gaishorn and Leoben locations,

- Open day with more than 1000 guests on June 24, 2023.

MM TIMBER LOG: Wood as key material against the climate crisis

As a sustainable raw material, wood plays a central role in the Green Transition. DI Richard Stralz, Chairman of the Board and CEO of Mayr-Melnhof Holz Holding AG, talks about new possible applications for one of mankind’s oldest and most time-tested construction materials.

Mister Stralz, let us talk about wood. It is one of mankind’s oldest and time-tested construction materials. For millennia, it was indispensable both as construction material and fuel. What is it used for today?

Well, basically for the same purposes and actually to an even greater extent. Over the past 10 to 20 years, we have seen a rising demand driven by efforts to use more climate-friendly, sustainable resources, which has lead to a true renaissance of this type of material. In today’s building construction we use solid timber in the form of glued-laminated timber and cross-laminated timber, but it is also used as construction timber and for veneering. Not only is it easy to process, it is also renewable and regionally available. It is an essential component of solving our climate issues. Let’s not forget: One cubic metre of wood is able to bind one ton of CO2 – in the form of trees, wooden furniture, wooden windows, timber construction buildings or even wooden toys.

So you could say that using wood creates sort of a second “forest” made of wood products, since the carbon remains stored in the processed material. At the same time, reafforestation creates new wood that also binds carbon and supplies oxygen to the environment. In addition, we have an important substitution effect: wood replaces other CO2 -intensive, non-renewable materials and thus prevents the CO2 –emissions their production would cause. Here we have the greatest leverage for climate protection. Products made in Austria and made of Austrian wood save about eight million tons of CO2. This is about one tenth of all greenhouse gas emissions in Austria over the period of one year.

Evidently, wood is unrivalled as construction material and raw material when we speak about its CO2 -balance. This is an enormous potential that we can use for our future.

Theoretically speaking, could wood replace all other construction materials?

Not in every single case, but certainly for a whole host of applications. You would not use timber to construct a basement, for example. Every construction material has its pros and cons and should be used where it best meets the requirements. Wood has many compelling arguments on its side, one of which is its low net weight and yet very high level of rigidity. If you want to add additional floors to an existing building, for example, wood is an excellent alternative. You don’t need to use more valuable land that is always scarce in urban areas by putting up a new building. In nearly all cases you can add one or two floors by using wood. Structurally, this is no problem at all.

Do we use enough wood in construction?

When it comes to using wood in construction, I call on the competent political decision-makers and public entities to join forces. We know that about one third of the world’s CO2 output is caused by cement and steel production. This is where we can really make a difference. If we want to do something for the climate, we must ensure that more wood is used. It should be promoted in public buildings such as kindergartens, schools, nursing homes etc. One thing is fore sure - there is no shortage of available wood to achieve this. In Austria alone, enough new wood grows every 30 seconds to build an entire single-family home. Over the last 25 years, forest resources here have grown by 23 percent. This value is even higher in the rest of Europe. Sometimes Scandinavia is criticised for its forestry, but even there wood is growing, not dwindling. Sweden, for example, only harvests 90 percent of its annual, renewable growth.

Do you see any novel areas of application of wood in the future?

Certainly, yes, because wood has not only become exactly calculable in terms of fire protection requirements but also in terms of its mechanical properties. The project Wood.C.A.R. by the Styrian Wood Cluster has been an essential contribution. Today we are able to precisely predict the behaviour of wooden components in the automotive area by using simulation models, so much so that we are able to minimise the use of expensive and complicated crash tests. This computability will enable many more applications for wood and wooden construction materials.

Does wood have a future as fuel? After all, it is climate-neutral if it is used this way.

Wood is proven to be CO2 –neutral. The use of its thermal energy has a long-standing, successful tradition. However, we have a duty to maximise the use of our raw materials as long as possible along the value-added chain to achieve true sustainability and use them efficiently and ecologically, no matter what type of raw material we choose to employ. This means that we must start with the most high-value product possible, and then recycle this valuable material prudently until we reach the end of the line and use its thermal energy potential. This process would normally take several decades and involve many different products.

Our domestic timber industry is often criticised for importing too much wood, especially from Eastern Europe...

Well, the Austrian timber industry procures logs from neighbouring countries, but our domestic forests are our raw material sources number one with an approximate 65 percent share in all processed round wood. You also have to keep in mind that about 80 percent of the Austrian sawmill capacity is located near our national borders. So, including purchases on both sides of the border comes natural, because sawmills routinely have a procurement radius of about 100 to 150 km. In turn, the same holds true for foreign sawmills near our borders, of course. Due to the current EU sanctions, no wood or wooden products are imported by the EU from Russia. Before the Ukraine crisis, about 10 percent of the European demand for all types of wood products was covered by imports from Russia and Belarus.

Recently, the EU has taken a critical stance towards wood. Is that a reasonable approach?

The EU wood and biodiversity strategy is not well thought out. On the one hand, the use of wood is promoted, and on the other hand timber harvesting is being restricted drastically. Yet, the responsible actors know very well how important it is to cultivate our forests.

Why?

Only cultivated forests are climate-resilient forests and will be able to deliver their much needed contributions to the solution of our climate change-related problems. Leave a forest unattended for merely 50 years and you will have turned a once CO2 –saving depot into an active source of net CO2 –emission, because of natural rotting processes. Timely timber harvesting and usage for long-term wood products as well as reafforestation of harvested areas keep our forests safe as carbon stores and oxygen producers. Young forests between 40 and 60 years absorb the most CO2. Sustainable forestry and wood processing combined get the best results for climate protection, because you get both maximum CO2absorption by the forests and extended carbon retention in the wooden products. In addition we support the biodiversity of our forests, a resource our woods need in order to be able to adapt to climate change.

So climate change also changes the timber industry?